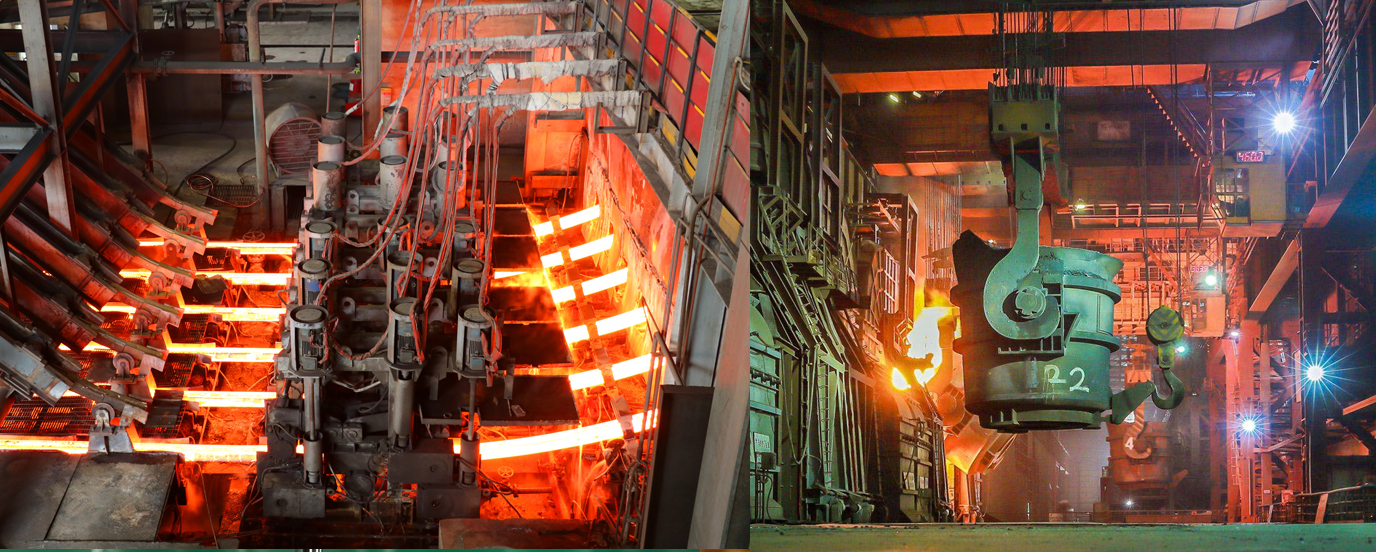

As one of the representatives of heavy industry, the production process of iron and steel metallurgical enterprises has the characteristics of complexity, large scale and high technology content.In order to ensure the safety, stability and efficiency of production, iron and steel enterprises need a large number of instruments to monitor and control the production process.With the continuous development of science and technology, the application of automation instruments in iron and steel metallurgical enterprises is more and more common. Effective use of automation instruments can improve production efficiency, reduce production costs, and also can improve product quality and production safety.

The effective application of automation instruments in iron and steel metallurgical enterprises is mainly reflected in the following aspects:

1.Real-time monitoring of production process

The high temperature, high pressure, harmful gas and other environment in the process of iron and steel smelting have caused great harm to personnel and equipment, so it is necessary to monitor the production process in real time through automatic instruments.By using sensors, measuring instruments and other automatic instrumentation equipment, we can monitor the changes of temperature, pressure, flow and other parameters in the production process in real time, find problems in time and take appropriate measures to ensure the safe and stable operation of the production process.

2.Control system optimization

In the process of iron and steel smelting, it is necessary to accurately control the furnace temperature, furnace pressure and composition of molten iron to ensure the quality of molten iron and production efficiency.Automation instruments can monitor these parameters in real time and optimize the control system to achieve accurate control of the production process and improve production efficiency and product quality.

3.Data Analysis and Statistics

Automation instrumentation equipment can collect various parameters in the production process in real time, and store, analyze and count them.Through the analysis of these data, we can find the problems and hidden dangers in the production process in time, and provide scientific basis for production management decision-making.

4.Equipment condition monitoring and maintenance

Iron and steel smelting enterprises have a large number of production equipment, including blast furnaces, rolling mills, heat treatment equipment, etc. The normal operation of these equipment is very important for the continuity and stability of production.Automation instruments can monitor the operation status of equipment in real time, analyze and evaluate the operation parameters of equipment, find out the problems of equipment in advance, and maintain them in time to ensure the safe and reliable operation of equipment.

5.Environmental Protection and Energy Conservation

A large number of waste gas, waste water and solid waste are produced in the production process of iron and steel metallurgical enterprises, which cause serious pollution to the environment.Automatic instruments can monitor and control waste gas emission, waste water treatment, energy consumption and so on, reduce the impact on the environment, and achieve the goal of environmental protection and energy saving.The effective use of automation instruments in iron and steel metallurgical enterprises can improve production efficiency, reduce production costs, improve product quality, ensure production safety, and achieve the goal of sustainable development.In the actual application process, there are still some problems and challenges to be solved in the selection, application and maintenance of automation instruments in iron and steel enterprises.

In the selection of automation instruments, iron and steel enterprises should select automation instruments with stable performance and high reliability according to their own production characteristics and needs.It is necessary to fully communicate with the instrument and equipment suppliers to clarify the functions and performance indicators of the products, so as to avoid unnecessary losses caused by product mismatch in the later period.In the application of automation instruments, iron and steel enterprises need to strengthen the training and management of application technicians to ensure that they are skilled in the use of automation instruments and improve the stability and reliability of equipment.In the maintenance of automation instruments, iron and steel enterprises need to establish a sound maintenance system, regular inspection and maintenance of automation instruments and equipment, timely detection and troubleshooting to extend the service life of equipment.